You’re here because you want to know why is my epoxy separating on my tumbler. The good news is that we’re here to tell you why.

In this guide, we’ll talk about how to avoid some common mistakes that can cause your epoxy tumbler to get fisheyes and divots or pinholes.

The last thing you need to experience is putting in all that effort and dedication to create your beautiful epoxy tumbler, only to have it get ruined before it is over. So, what causes the epoxy to separate?

What Causes Epoxy to Separate?

The most common cause is contamination. The contamination can be in the form of dust particles, wax, oil from your fingers, and much more.

This is why we’re always very adamant about you choosing a good workstation that is free from contaminants. So, the contaminants make your epoxy separate by disrupting the epoxy’s surface tension.

You can think of the epoxy running away from the contaminated area. Unfortunately, this is what ends up ruining your smooth coat. Another imperfection you may have heard of when it comes to epoxy is pinholes.

Pinholes are formed when air bubbles form within the epoxy resin when you are applying it. The tricky part about pinholes is that they are only visible after the epoxy has cured.

Therefore, you can use the right amount of epoxy and think that everything is fine, only to find the pinholes after the curing process is over.

So, now that we know what causes your epoxy resin to separate let’s look at how to avoid this from happening in the first place.

How to Avoid Epoxy from Separating on Tumbler

If you want to prevent the formation of fisheyes and pinholes, you’ll need to pay attention to your workstation and the curing process. First, let’s look at what to do and what not to do in these stages.

A) Ensure Proper Preparation for A Smooth Epoxy Coat

Preparation is key in everything you do, and creating your epoxy tumbler it’s no different.

Here are 5 important tips to keep in mind.

1. Ensure that your workstation is clean and properly ventilated

However, even though you want proper ventilation, ensure that the airflow is minimal and won’t introduce any contaminants to your tumbler.

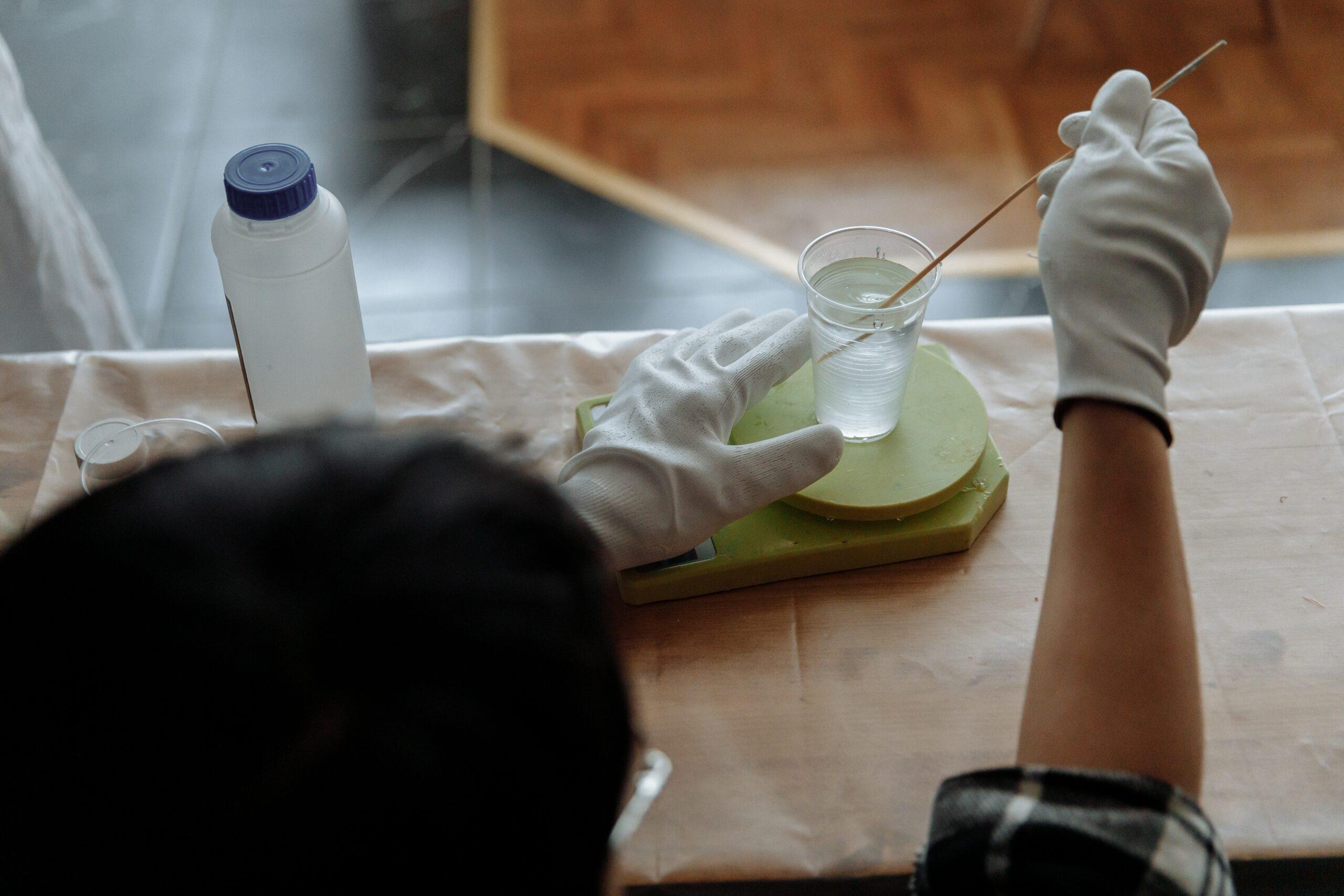

2. Use clean equipment during application

You don’t want to introduce any contaminants to your epoxy before it cures. Therefore ensure that your gloves are clean.

If you are using a soft brush, ensure that it’s clean to avoid any particles getting stuck between the resin layers.

3. Apply some alcohol

You can use some Denatured Alcohol (DNA) to pick up any contaminants or oils that may still be stuck to the surface of your epoxy tumbler before applying a second coat.

Ensure that the alcohol is completely dry before you apply the second coat.

4. Ensure the temperature remains the same

Once you’ve chosen the best epoxy for tumbler to use, place it on the workspace so that it can be at the same temperature as the tumbler.

This is to prevent a rapid change in temperature, which can cause the resin not to spread out evenly. Therefore, always ensure that the resin and the tumbler are at the same temperature before you start applying.

B) Be Careful with Wet Epoxy

We’ve covered how to ensure that the workspace is good and free of contaminants. Now, let’s see how to handle your tumbler after you’ve applied your epoxy.

Here are some simple tips to remember.

1. Avoid touching the wet epoxy

Once you’ve put the final epoxy coating, avoid touching it for at least 10 minutes after you’ve finished applying it. In fact, you should avoid any movements or disturbances around your workstation.

This is to prevent kicking up any dust particles that may settle on your newly done epoxy tumbler. Remember that YouTube video you’ve been saying you’ll watch or that text you’ve kept on saying you’ll reply to? This is the time.

Just sit still and watch your epoxy dry for about 10 minutes before you come back and access consistencies. After the 10 minutes, add another seal coat if you feel the need to.

2. Avoid brushing over inconsistencies

This is more of a warning than a point, but you need to ensure that you don’t take a brush and try to fix the fisheye, as this will only make it worse hence denying you that nice smooth finish.

Final Thoughts

Now that you know why your epoxy is separating don’t forget to follow the tips we’ve covered as you work on your epoxy tumbler. This will prevent you from having to redo the process all over again.